European Young Engineers

The voice of young engineers in Europe

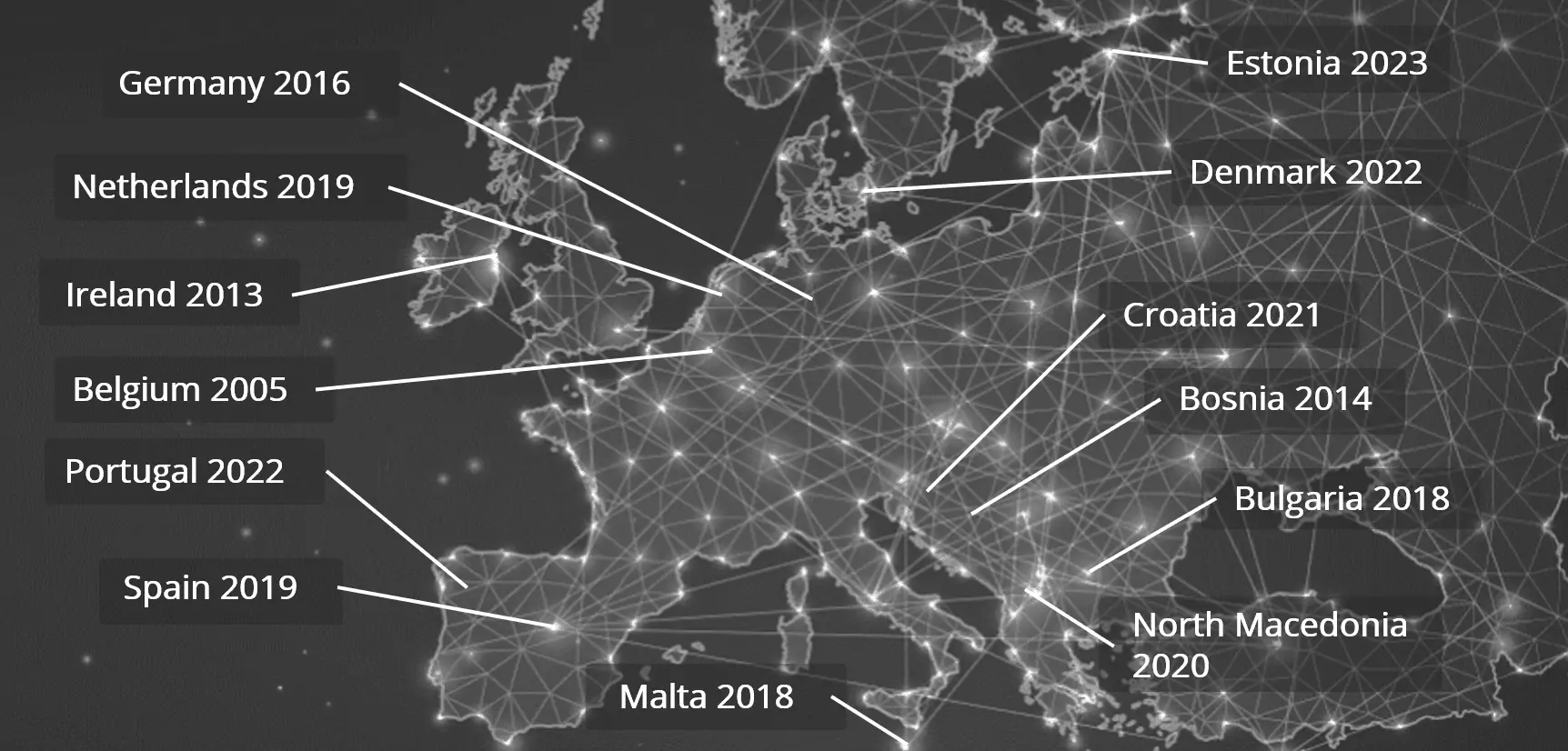

European Young Engineers (EYE) is an international non-profit organisation (est. 1994) comprising more than 20 European countries that represents about 500,000 young engineers from multiple disciplines.

Join the next conference in Limerick!

16 – 19 May 2024

Picture by Michael Starkie on Unsplash (license)

Vision

European Young Engineers aim to be the voice of young engineers in Europe.

Mission

Form a political opinion of engineers across Europe (form a voice)

Be a stakeholder for governmental bodies (make voice heard)

Collaborate with the industry, politicians and academic associations (get into dialogue)

Strategy

Networking, building mutual understanding, and providing skills

Foster collaboration between engineers in Europe and beyond

Be the leading platform for young engineers in Europe

News

EYE Impact Report 2022

Read EYE’s first impact report highlighting the activities we have been collaborating with various industries.

Apply to EYE’s 2023/2024 Management Board!

Apply now to become the next (Vice) President @EYE.

Detailed information in this post.

Audi Hackathon – 1 April 2023

Together with our partner Audi we proudly announce the “Audi Hackathon on how AI impacts engineering” on the 1 April 2023

Together we shape the future of Europe

EYE conferences

Twice a Year

Interdisciplinary Speakers

Networking Events

Gala Dinner

Industry Visits

Be part of EYE!

Attend our events!

Do you want to get to know the international family of Europe’s young engineers? Then attend our conferences, webinars, workshop, and more!

Volunteer with us!

Do you want to work on international projects and foster the voice of young engineers in Europe? Then be part of our team and generate impact!